Flexo printing inks

UV printing inks

Printing solvents

Lamination adhesive

Flexographic Mounting Tape

Doctor blades and flexo seals

Printing adapters

Printing sleeves

Test pens for quick test of film surface energy

Flexo printing inks

UV printing inks

Printing solvents

Lamination adhesive

Flexographic Mounting Tape

Doctor blades and flexo seals

Printing adapters

Printing sleeves

Test pens for quick test of film surface energy

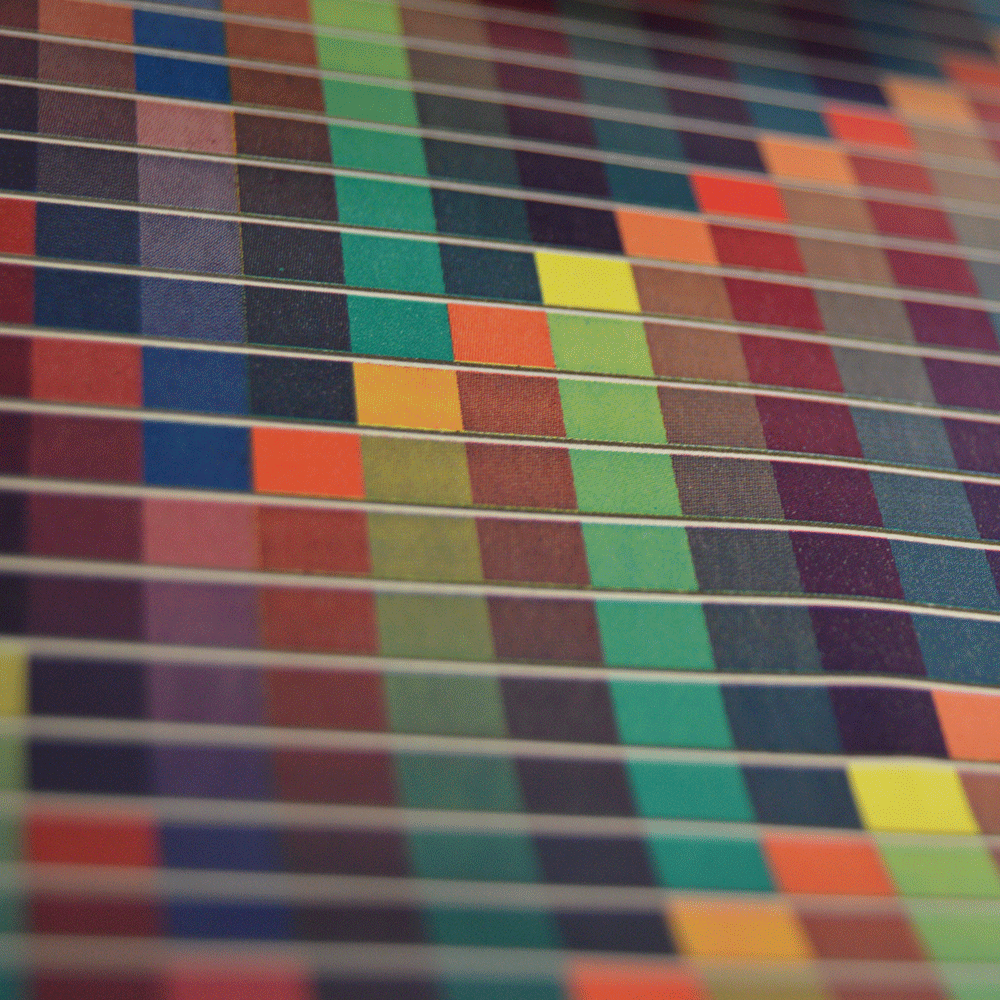

Flexo & rotogravure printing inks

Our inks are available in a wide range of colors which can occasionally be limited by the selection of pigments suited to particular specification and requirements. The pigments used have reasonable light fastness but may not be suited to extended exposure to direct sunlight. If higher light fastness or other specific resistances are required this should be stated at the time of ordering.

– Solvent-based inks for PE and PP for standard and high speed printing

– Water-based inks for HDPE films and bags

– Polyamide inks for PP fabric with high light resistance

– Water-based inks for paper, cardboard and corrugated cardboard

Flexo and rotogravure surface and lamination printing on:

HDPE

PAPER

Plain BOPP

Pearlized BOPP

Meallized BOPP

Coex BOPP

Aluminium foil

High quality and economy inks and lacquers. Our advantages:

Good opacity

High gloss

High adhesion

High printability

Excellent scratch resistance

UV printing inks

Ink systems and varnishes for label printing is one of our divisions.

Label printing inks must exhibit a wide range of fastnesses and resistance to a diverse assortment of packaged products. They must adhere to a wide range of plastics and be suitable for high-speed printing machines.

UV-Flexo Printing Inks

UV-Flexo fluorescent inks

UV-Letterpress inks

UV-Offset inks

UV-Screen

UV-Waterless

Low Migration Ink Systems

|

PROCESS |

TYPE |

INK SERIES |

LACQUERS |

|---|---|---|---|

|

Flexo |

H2O based |

Series WB LM |

Series WB LM 39-10LM (UV-OPV) 39-20LM (UV-OPV) |

|

UV radical |

SICURA Flex 39-10LM SICURA FLex 39-20LM |

39-10LM (UV-OPV) 39-20LM (UV-OPV) |

|

|

Offset |

UV |

SICURA LM 100 (Paper/PE) SICURA LM 361 (Paper/PE) SIDURA Plast LM (Plastics) |

39-10LM (UV-OPV) 39-20LM (UV-OPV) |

|

UV Waterless |

SICURA Plast WL-LM |

Standard Ink Systems

|

PROCESS |

TYPE |

INK SERIES |

LACQUERS |

|---|---|---|---|

|

Flexo |

H2O based |

UNILABEL T (Thermal Paper) Aqualabel (Paper) |

Unilabel T 85-601679-5 (UV-OPV for Thermal Paper) |

|

Solvent based |

Series 75 |

Series 75 |

|

|

UV radical |

SICURA Flex 39-8 SICURA Flex 39-3 (Low Odour) SICURA Flex 39-4 (Fluo) |

SICURA Flex OPV SICURA Screen OPV |

|

|

UV cationic |

Sicura Flex 36-2 and 37-5 |

SICURA Flex OPV (cationic) |

|

|

Screen |

UV |

SICURA Screen 78-3 SICURA Screen 78-6 (Whites) |

SICURA Flex OPV SICURA Screen OPV |

|

Offset |

UV |

SICURA Plast SP SICURA Plast LO (Low Odour) SICURA Litho 900 (Paper) SICURA Card 37700 |

SICURA Flex OPV SICURA Screen OPV |

|

UV-Waterless |

SICURA Card 110N/WA SICURA Plast 41-WL SICURA WL Disc (CD/DVD) |

SICURA Flex OPV SICURA Screen OPV |

|

|

Gravure |

Solvent based |

Series 97-4 (Lamination) |

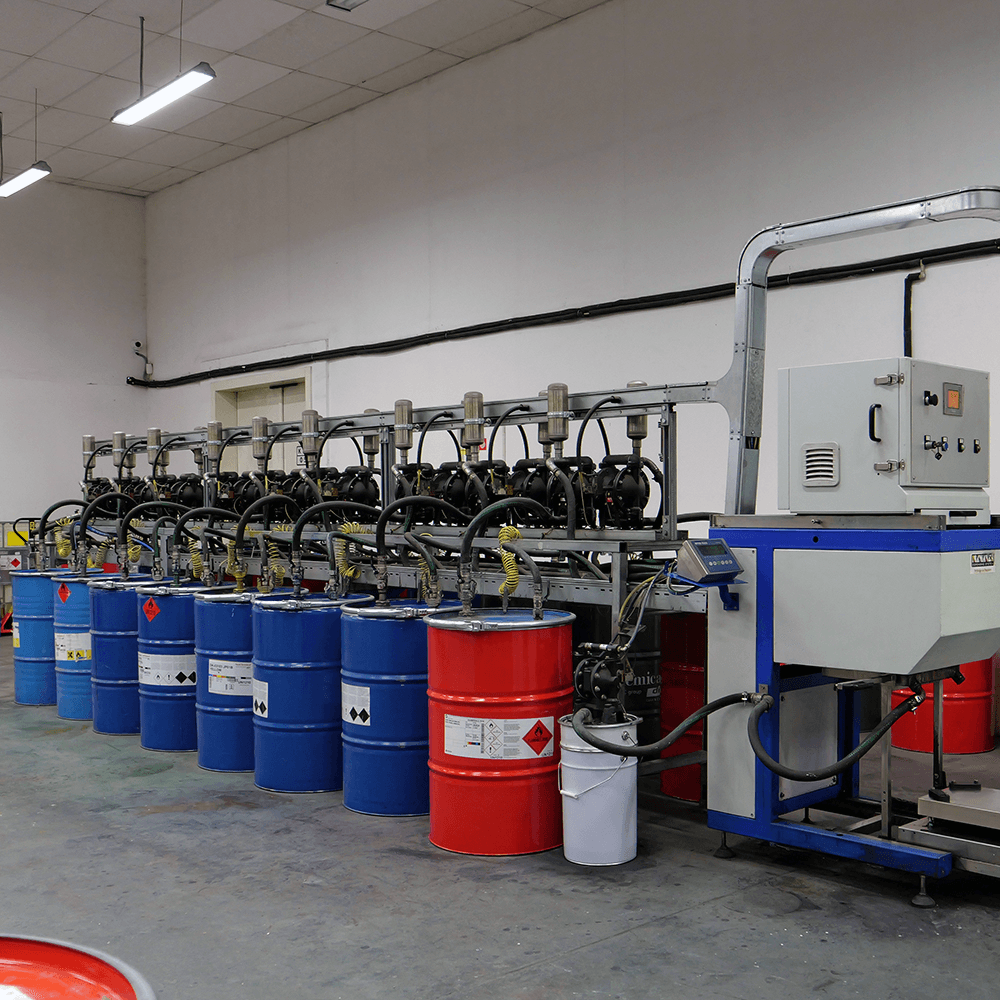

Printing solvents

– Ethylacetate

– Methoxy propanol

– Ethoxy Propanol

– Isopropyl alcohol

High quality printing solvents delivered in drums, IBC and bulk.

Lamination adhesive

Whether your goal is to customize packaging applications or to improve efficiency without sacrificing performance, Dow works with you to define the challenge and deliver a unique solution, every time.

ADCOTE™ one and two component solvent based laminating adhesives and heat seal coatings for food, medical and industrial packaging applications, and some printing applications.

– Light and easy to carry, open and dispose, high thermal resistance.

MOR-FREE™ L are one- and two- component solventless adhesive systems for laminating flexible substrates.

– Lower energy consumption and CO2 emissions ROBOND™ L are one- and two-component, acrylic water-based adhesive systems for laminating flexible substrates.

– Acrylic technology for healthier and cost-effective food packaging.

ROBOND™ CS

Aqueous, latex-based cold seal dispersions for laminating flexible substrates.

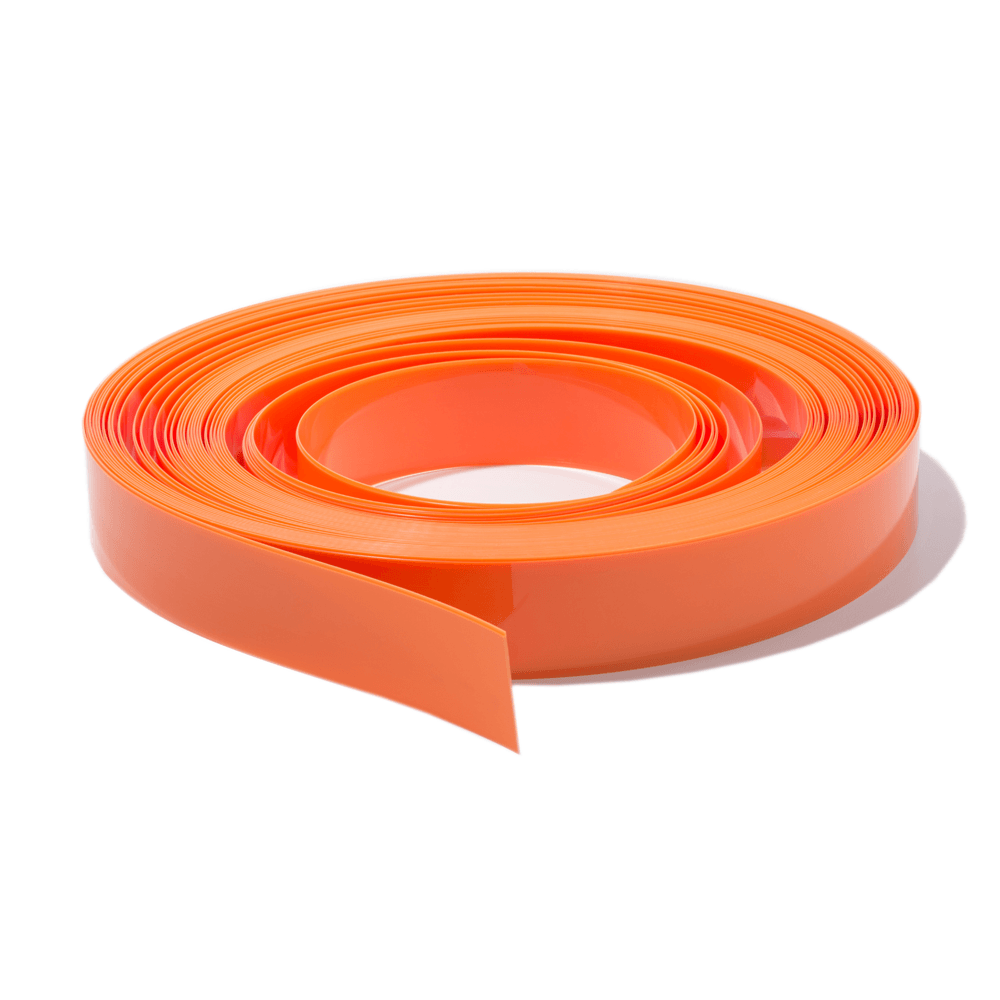

Flexographic Mounting Tape

For halftone work where dot gain is a concern, a softer tape optimizes reproduction.When solids and dots share the plate, a combination tape can properly balance the result.When your customer requires solid ink and crisp lines, you’ll want a firm, high density mounting tape. From the wide 3M selection, you can find the adhesives, foams, and thicknesses for the print quality that customers demand and expect. You’ll also find choices to meet your handling requirements for:

– Mounting ease and positioning accuracy

– Easy, clean removal from plate and cylinder

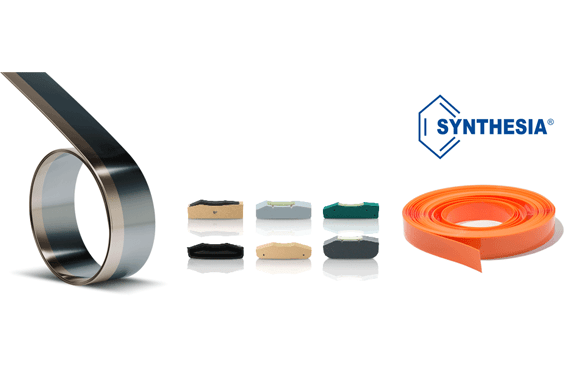

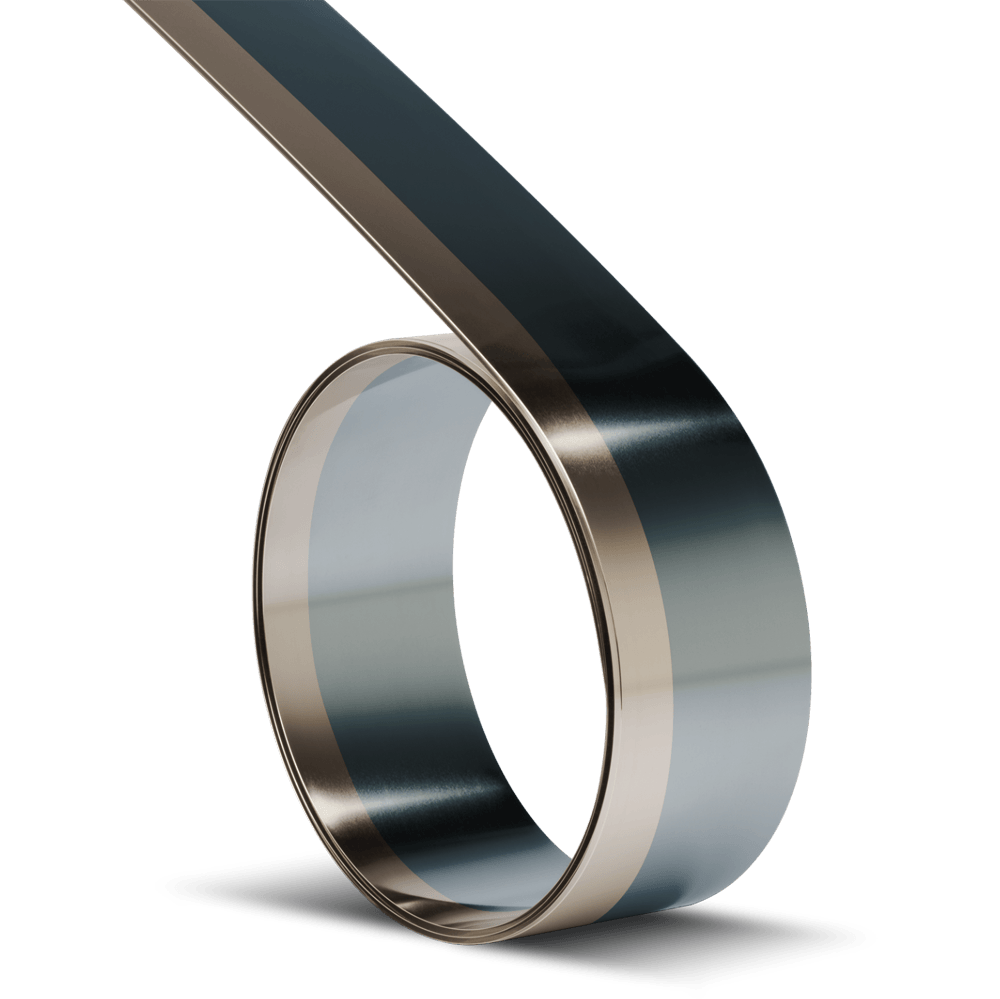

“PROBLADE” steel doctor blades for Flexo and Gravure

The offered doctor blades are made of high quality hardened Swedish steel! High quality at super competitive prices!

The steel doctor blades are made of high-quality steel (Sandvik C20) on “MDC” (evolutionary) machines; the standard slope guarantees perfect ink peeling, excellent duration of use and no chipping.

This metal doctor blade knife is designed for gravure and flexo.

- Materials: Extremely clean steel that prevents micro defects on the slope surface

- With or without bevel (MDC type – evolutionary) depending on the size and thickness of the doctor blade

Sizes of doctor blades:

- Width: from 10 to 60 mm

- Thickness: 0.15, 0.20, 0.25 (0.30 on order)

- Length: rolls of 100 meters

Synthesia Ltd. offers a wide range of plastic doctor blades

Each doctor blade has its narrow application.

Plastic doctor blades are characterized by the materials from which they are made, their shape, their quality in terms of efficiency, durability, safety, price and their performance.

Each printing press requires a special doctor blade.

We offer you the widest selection on the market.

Flexo seals

High precision seals with strict tolerances made of 5 different FOAM grades suitable for all applications (solvent base, water base, UV) aimed to a proper ink chamber sealing and a long lasting (up to 250-300’000 m runs). Seals are produced with any shape on demand, using CNC technology with high cutting precision which grants a smooth contact surface seal-cylinder. Extreme flexibility in manufacturing out of samples and drawings as well as in modifing shapes & sizes.

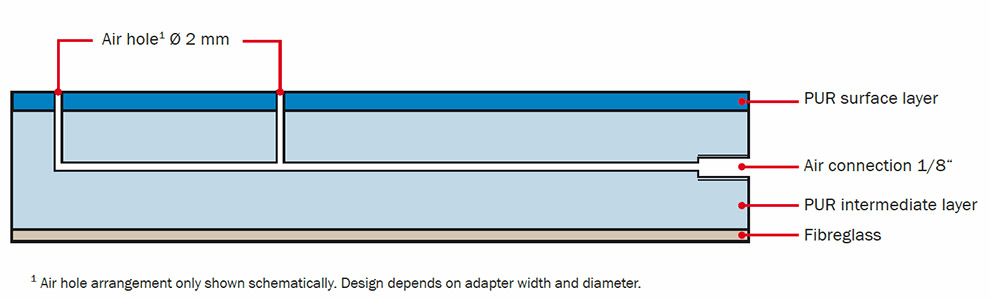

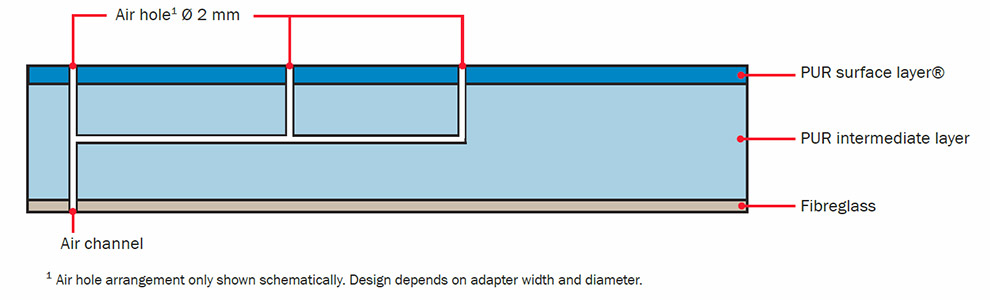

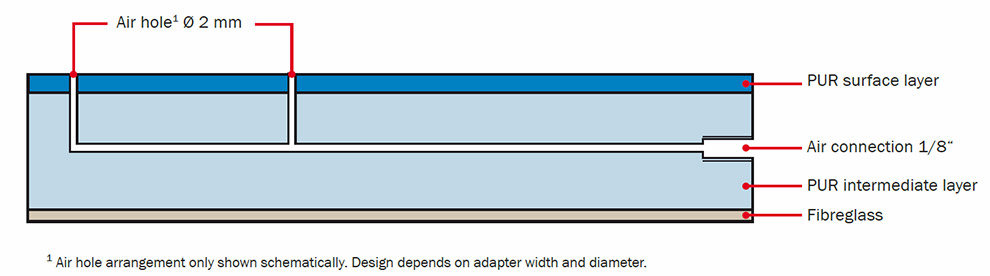

Printing adapters

- Quick set-up times, easy handling and cost saving

- Optimal air flow for easy mounting of sleeves

- Suitable for conventional cylinder presses and quick change cantilevered machines

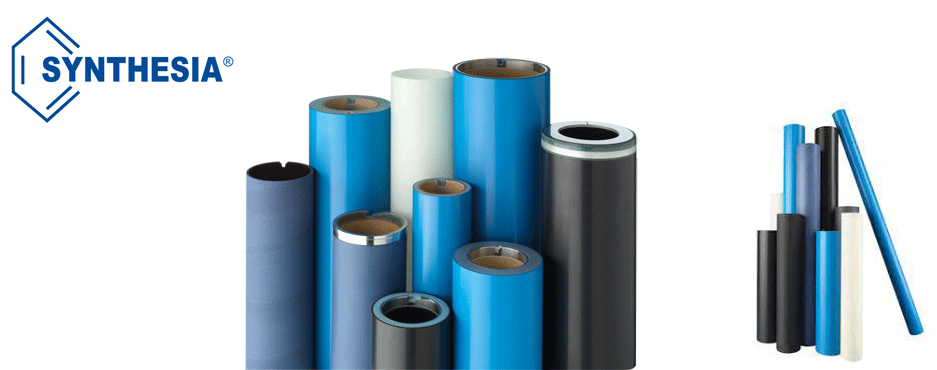

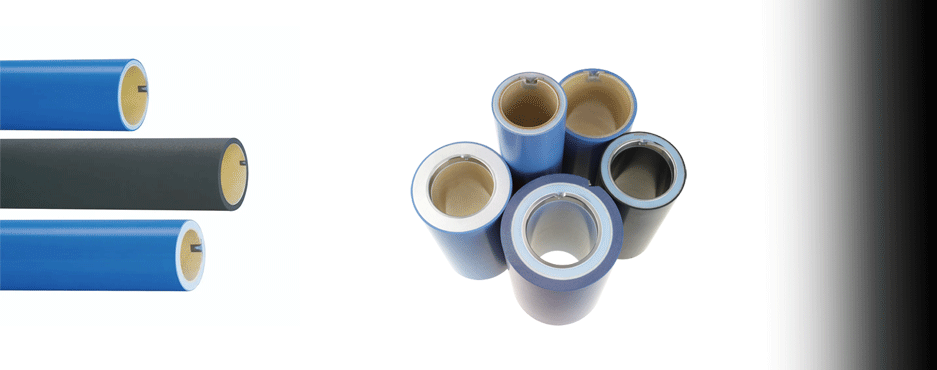

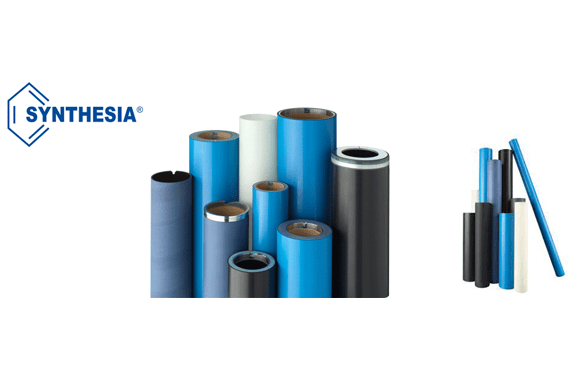

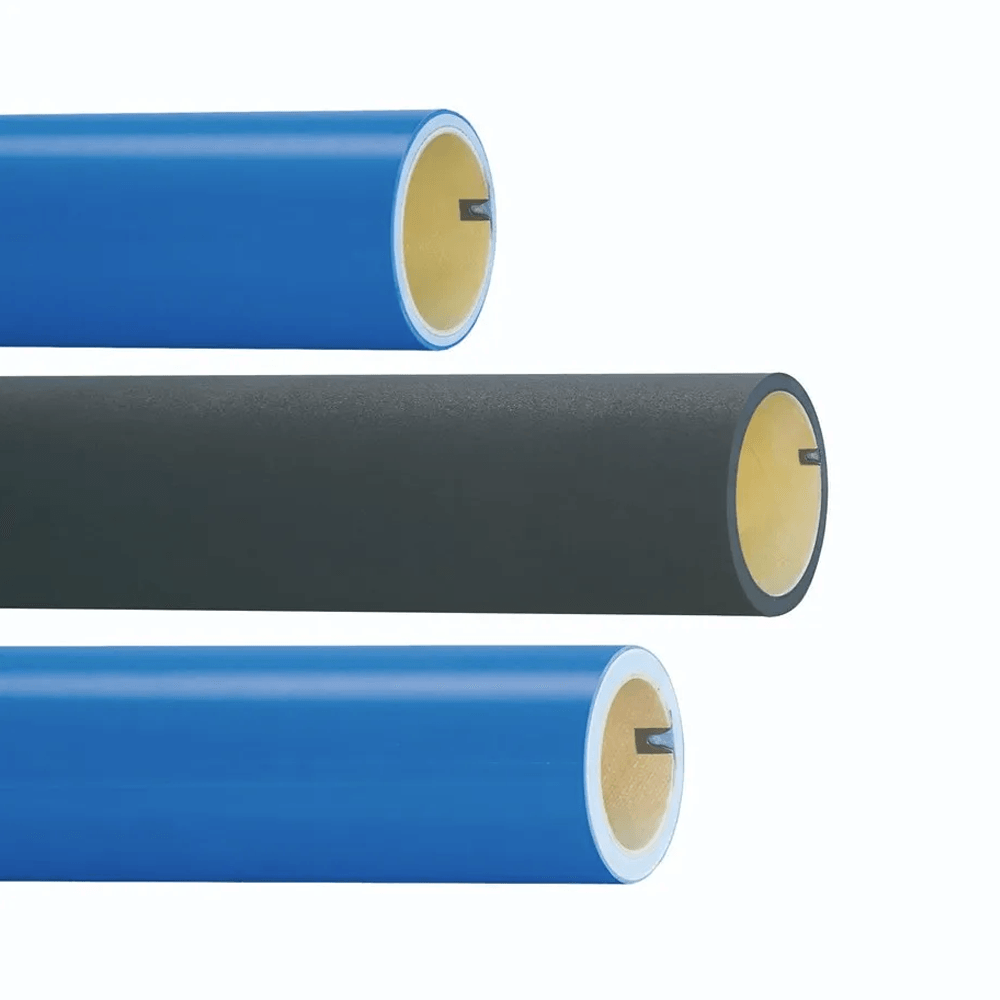

Printing sleeves

- Easy and reliable handling for all plate types

- TIR < 0.025 mm

- Proven rotec® interior design of synthetic resin and glassfibre compound

- High durability and stability

Test pens for quick test of film surface energy

Treated and untreated plastic films are indistinguishable to the naked eye. Usage of insufficiently treated films causes delays and waste, which can quickly became a major problem in an industry that demands highest levels in quality, performance and production output. This is especially true in the converting industry, so information needs to be available quickly and simply.

To perform the test, a line of ink is applied to the film with the pen and the behaviour of the ink observed. If the ink forms a solid line, the film has a surface energy of at least 38 mN/m and can be used for printing and other converting steps. If the ink contracts and does not form a solid line, the film’s surface energy is below 38 mN/m. This indicates that the film is insufficiently treated for most converting processes.

Its ease of use, reliability and competitive price have made our product the no. 1 best selling corona test pen in the world!

Besides test markers for DIN 38 mN/m. we also offer various surface tension test kits from DIN 34 – 36 – 38 – 40 – 42 – 44 – 46 – 48 – 50 – 52 up to DIN 54