Distribution

Ink dispensing

Lab testing services

Technical services

Reach

Contacts

Distribution

Ink dispensing

Lab testing services

Technical services

Reach

Contacts

Distribution

Ink dispensing

For optimal results we need to know:

Your PANTONE shade desired color or TARGET SAMPLE

Type of the ink: water or solvent based

Nature of the printing substrate

Color of the printing substrate

Required basic and/or overprint lacquers

Ink transfer

Printing press type

Printing speed

Lab testing services

We can check you final product or to analyse your competitor product with the following tests:

Analytical Testing

IR absorption

UV spectrometry

Spectrophtocolorimeter

Nitrogen analyser

Atomic absorption

DSC

TGA

HPLC – GC

Moisture – Volatile analysis

Microscopic analysis

Physical Testing

Viscosity

Ash mineral content

Pressure rise & dye build up

COP

Optical density

Sealing properties

Mechanical properties

Anti-Fog properties

Accelerated weathering

Antistatic properties

Plastics:

Color matching of existing masterbatches and developments of counter-types.

Development of color masterbatches under RAL or PANTONE.

Printing:

Development of flexo printing solvent and water based inks under PANTONE.

Analysis of:

Viscosity

Pigment concentration

Technical services

Some of our service:

We can recommend you recipes for production of wide range mono or multilayer films.

We can recommend you different structure of foils for different applications based on our experience in other countries: for example agro foils, mulch films, stretch hood and ect.

We can propose you different recipes for polymer processing like blow molding, injection molding, film extrusion, pipe extrusion, extrusion coating, co-extrusions.

For printing we can recommend what is the best lacquer, ink or lamination adhesive for your project.

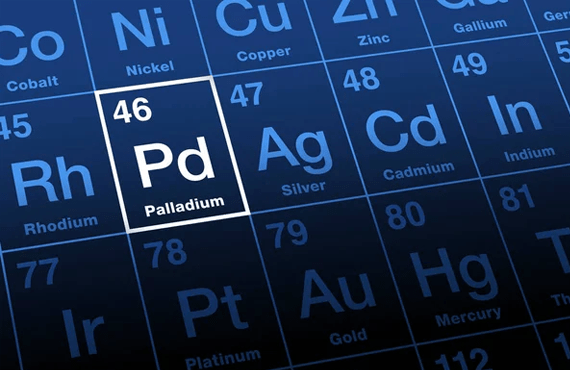

REACH

On 18th of December 2006 European Parliament validated Regulation No 1907/2006 and started a new system for registration, evaluation, authorization and restriction of production, import and use of chemical substances in the EU called REACH (from the Registration, Evaluation, Authorisation and Restriction of Chemicals). REACH completely replace all existing Directives (Directives 1999/45 / EC, 793/93, 1488/94, 76/769 / EEC, 91/155 / EEC, 93/67 / EEC, 93/105 / EC and 2000/21 / EU) for hazardous chemicals.

Essentially, REACH requires each manufacturer / importer of chemicals in quantities of more than 1 ton to register by submitting the information required under REACH to the European Chemicals Agency based in Helsinki, Finland.

Synthesia Ltd. supplies raw materials for the polymer and printing industry in Bulgaria within the scope of REACH regulation.

Synthesia Ltd. is a “downstream user” so far works with leading European manufacturers of industrial raw materials. Our suppliers have declared their place in the chain and are committed to fully meet the requirements set out in REACH. Identifying as “downstream user”, Synthesia Ltd. undertakes to:

Provide to all downstream users safety data sheets for substances and mixtures according to Article 31 and Annex II.

To prepare and make available for all downstream users information on non-classified substances as required by Art. 32.

To submit information for all necessary measures for risk management.

Synthesia Ltd. will continue to communicate with customers and vendors to fully meet the requirements set out under REACH, not only during the pre-registration and also in the following period until full implementation of REACH by 2018.